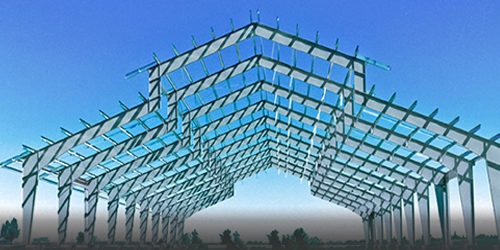

Customizable Steel Buildings: Customized Layouts to Fulfill Your Details Requirements

Customizable Steel Buildings: Customized Layouts to Fulfill Your Details Requirements

Blog Article

Effective Installment Practices for Steel Structures: Streamlining Your Construction Process

From meticulous preparation to the usage of pre-engineered parts, each step plays a crucial duty in speeding up the construction timeline. By diving into the world of advanced setup techniques and making sure strict top quality control actions, the capacity for optimizing the whole building process comes to be not just an opportunity but a functional reality.

Planning for Efficiency

When aiming to make best use of efficiency in steel building installation, precise planning is vital. Appropriate planning sets the foundation for a orderly and smooth building and construction procedure, inevitably conserving time and sources.

Additionally, effective communication amongst all stakeholders is critical throughout the planning stage. Regular conferences and updates help maintain everyone on the exact same web page, reduce misconceptions, and foster a joint working setting - steel buildings. By investing time and initiative right into precise preparation, steel structure installation can be carried out with accuracy and efficiency

Making Use Of Pre-Engineered Components

Effective steel structure installation methods can be even more improved by leveraging the application of pre-engineered elements. Pre-engineered parts are made and manufactured off-site to specific requirements, ensuring compatibility and simplicity of setting up during the building process. By including pre-engineered parts such as beams, trusses, panels, and columns, building contractors can streamline the setup process, lower on-site labor demands, and lessen construction waste.

One key benefit of making use of pre-engineered parts is the significant time cost savings they use. Considering that these parts are made in a regulated setting, they come to the construction site ready for fast and efficient setup. This not only speeds up the general construction timeline however additionally aids to lessen job hold-ups and connected expenses.

In addition, pre-engineered parts are crafted for ideal efficiency and architectural stability, making sure the long-lasting toughness and security of the steel building. By utilizing these standard parts, building contractors can attain regular high quality across different tasks while likewise taking advantage of cost financial savings connected with decreased material waste and labor expenses.

Maximizing Building Sequencing

To make best use of productivity and effectiveness in steel structure installation, calculated optimization of building and construction sequencing is critical. By very carefully planning the order in which tasks are carried out, building and construction teams can decrease downtime, lower product handling, and streamline the total structure procedure.

Applying Advanced Installation Methods

Applying advanced setup methods boosts the performance and quality of steel building construction projects. By integrating innovative approaches such as computer-aided layout (CAD) for precise planning, prefabrication of elements off-site, and use of innovative equipment like robot welders, building and construction groups can significantly streamline the installation process. CAD software enables for in-depth 3D modeling, assisting in the visualization of the last framework and making certain specific part dimensions for an excellent fit throughout setting up. Prefabrication minimizes on-site labor requirements and building time by fabricating building elements in a controlled environment, minimizing mistakes and revamp. Making use of robotic welders enhances the speed and precision of welding jobs, enhancing the general structural integrity of the steel structure. Furthermore, applying innovative methods advertises safety by reducing hand-operated labor needs and prospective workplace hazards. By welcoming innovation in setup methods, construction jobs can be completed quicker, with better outcomes, and within budget plan restrictions.

Making Certain Quality Assurance

Structure upon the application of sophisticated installment techniques, preserving rigorous quality control procedures is paramount in making sure the architectural integrity and dependability of steel structure tasks. Quality control begins with the option of high-quality materials that fulfill sector standards and specs. their explanation Normal inspections throughout the construction process assistance recognize any kind of deviations from the design or prospective problems that can endanger the structure's toughness.

Documentation is a vital facet of quality assurance, guaranteeing that try here all steps in the setup process follow the authorized guidelines and strategies. This consists of recording inspections, material certifications, and any adjustments made throughout building and construction. Implementing a clear interaction method among staff member and subcontractors helps streamline the quality assurance process and address any concerns immediately.

Conclusion

In final thought, embracing effective setup methods for steel buildings is important for improving the building process. It is important to prioritize efficiency in order to optimize performance and accomplish successful outcomes in steel building construction.

To maximize performance and performance in steel building installation, strategic optimization of building and construction sequencing is extremely important. Generally, by enhancing construction sequencing, steel structure installment can be completed more successfully, conserving time and costs in the procedure.

Carrying out sophisticated installation strategies improves the efficiency and top quality of steel building construction projects. By focusing on quality control throughout the installment procedure, construction groups can provide steel structures that are not only efficient however also sturdy and trustworthy.

In conclusion, embracing efficient installment practices for steel buildings is click for more essential for simplifying the construction procedure.

Report this page